AICS

EHS Management Service

The intelligent manufacturing safety platform tailored for success

Play Video

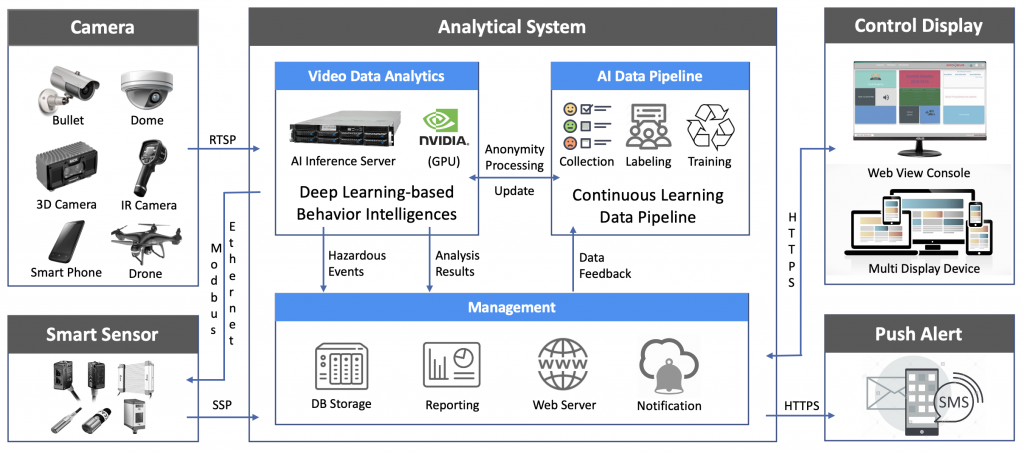

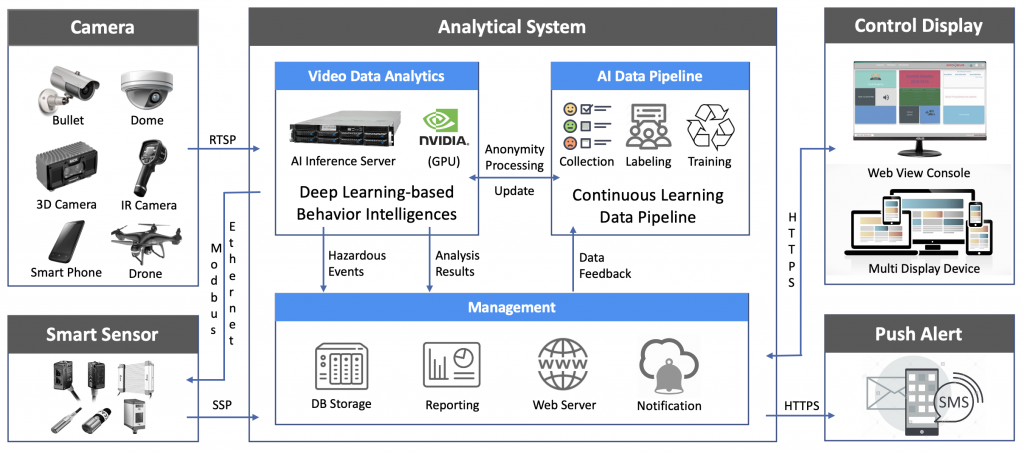

Artificial Intelligence solution that is turn-key, scalable, and agile, designed to align with international safety standards for greater production optimization and management.

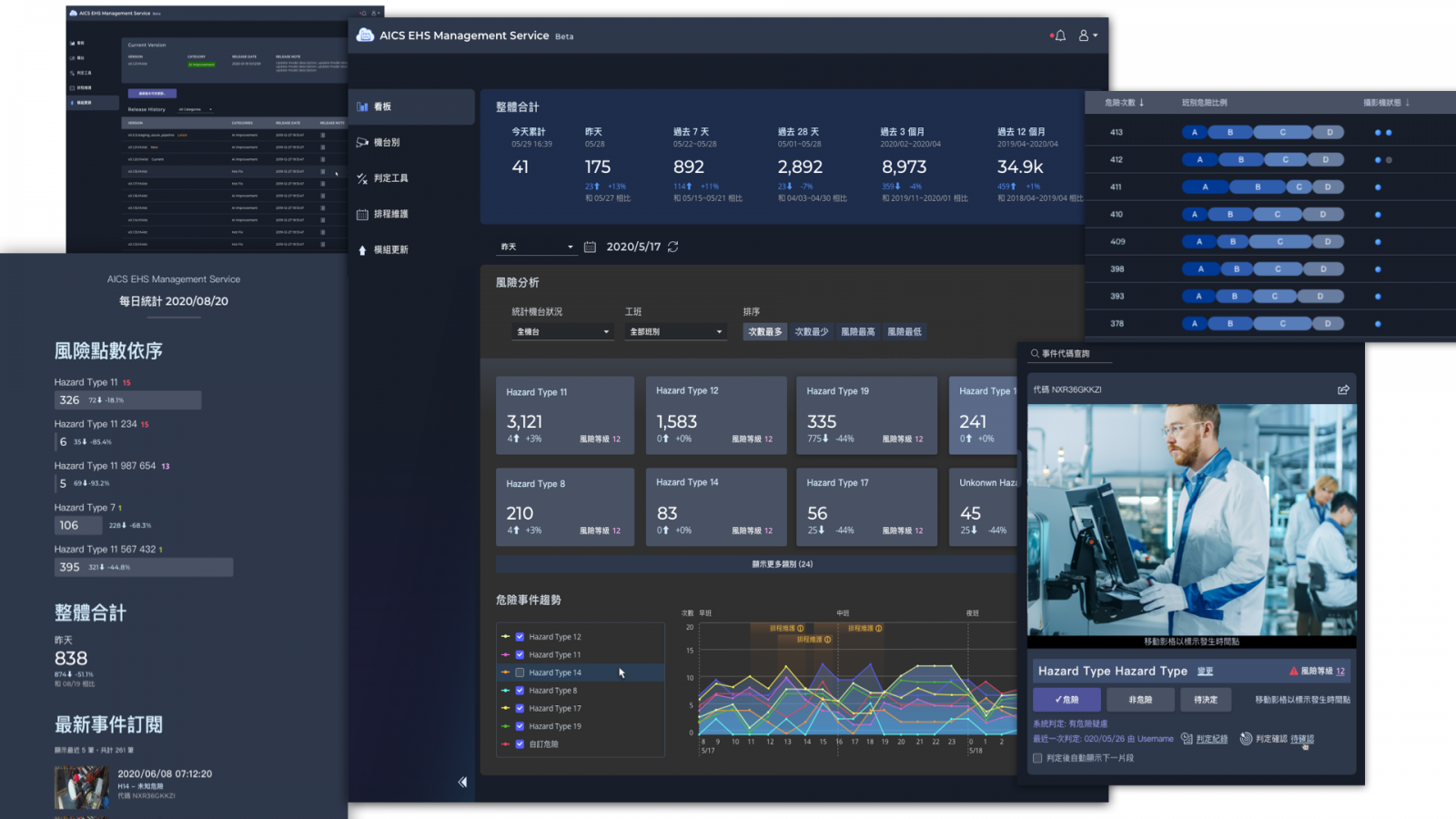

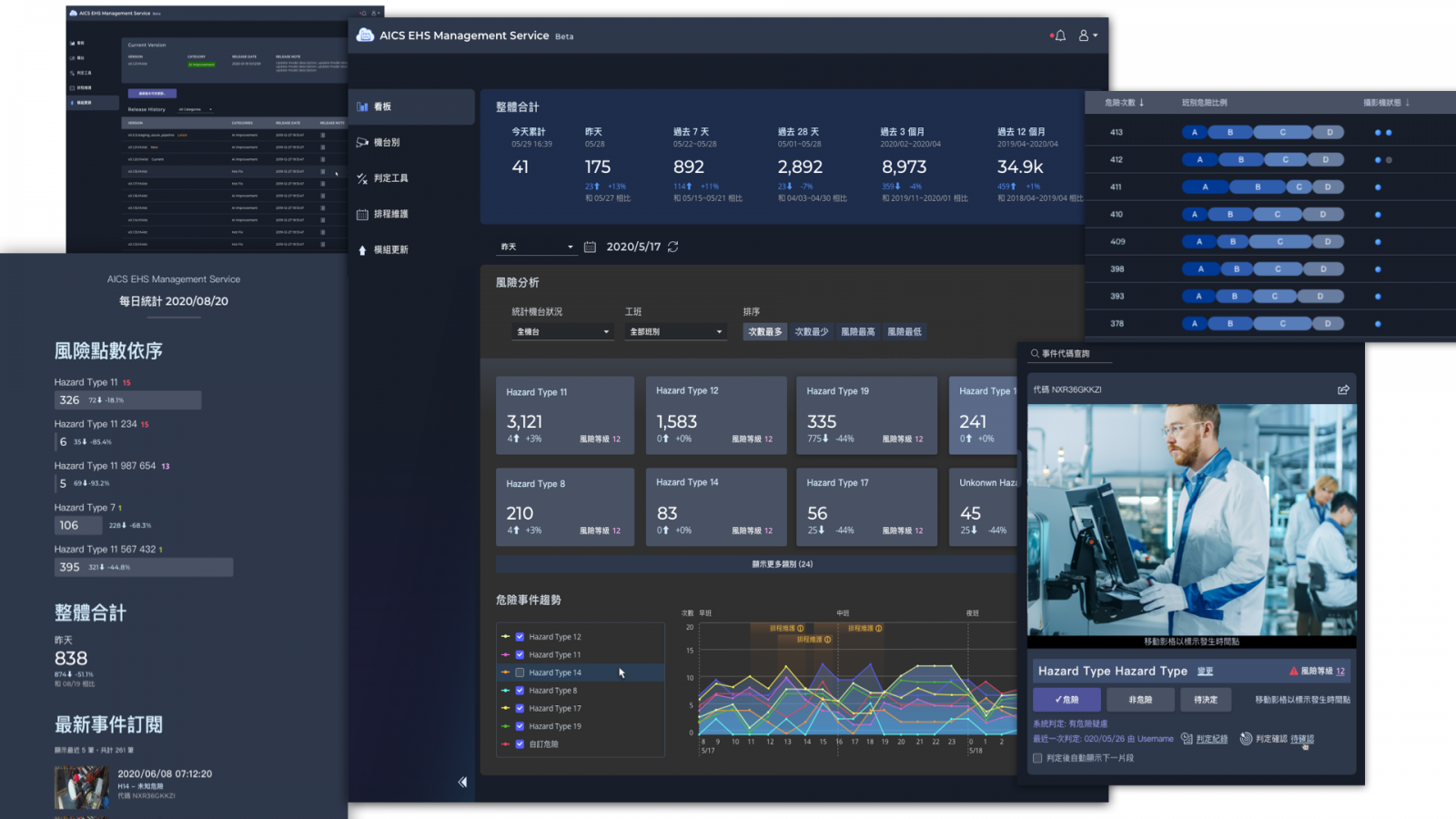

Customized for safety professionals to effectively manage frontline incidents remotely. Anomalous events are automatically detected and warning notifications are sent in real-time.

Improve standard operational procedures for occupational safety and minimize incident rates through smart monitoring, dynamic surveillance, and protection mechanisms.

Safety has always been the top priority of the Bridgestone Group. It is an honor to partner with AICS and implement the EHS Safety Management System during this transformative period of Bridgestone Taiwan. By applying cutting edge technology and artificial intelligence for big data analysis, we are therefore able to better secure the safety of our employees.

In Bridgestone Taiwan’s journey to transform into a smart factory, our worker’s safety is always a top priority. Through AICS EHS Safety Management System, not only has operational hazards been made quantifiable, but it has also allowed us to identify potential unknown hazards. This makes performance analysis and education workflows much more streamlined and effective. High-risk actions will receive real-time alerts and notifications for immediate correction to ensure workers’ safety, thereby giving us more confidence in driving towards a zero accident vision.

When a worker enters the operation area, our AI model can not only dynamically identify the person based on facial recognition, but can also check if his PPE attire (including safety helmet, mask, safety vest and etc.) conforms with the pre-defined rules and allow entry or issue warning.

With the virtual electric fence set up at a pre-defined zone, our AI model can not only detect if there are any unauthorized entries, but it can also track personnel movements across zones. This is especially useful in tracking personnel movements within the plant as different conditions can be assigned to various groups of people including workers, visitors, or contractors.

Our AI model can effectively identify complex operation actions according to pre-defined standard operating procedures and assign risk scores accordingly in real-time. Also, it will automatically detect anomalies and raise alert to such unknown incidents as potential hazards.

Most forklift accidents are due to human error. Our AI model can ensure that PPE adornment rules (helmet, safety belt, etc.) are adhered to, as well as ensure drivers operate the forklifts safely (one-handed driving detection, etc.). Dangerous operations such as high-speed traveling or overloading of forklifts can also be detected and alarmed in real-time.

Our AI model can dynamically detect the pointing confirmation procedures of all personnel (finger pointing and gaze detection), no matter if they are walking, operating machinery or driving, according to the pre-defined operating procedures. Detected events can be used for training and referencing purposes.

Join our mission to bring transformative change to the Healthcare industry with AI solutions.